HYPROVIDE®

X-SERIES

An outdoor modular, high-pressure electrolysis solution designed for scale.

- H2 production: 1200 Nm³/hour (109 kg/hour)

- H2 gas purity: ≥99.97%

- Stack efficiency: 51.9 kWh/kg H2

- Outlet gas pressure: ≥ 35 bar(g)

- Dynamic load: 25-100%

- Adjustment capability (from 25%-100%): <10 seconds

- Demineralised water consumption: 9.1 kg/kg H2

- Third-party Proof of Concept

- Third-party Safety assessment

- Third-party Proof of Performance

- +200 hours of uninterrupted performance, third-party validated

- Optimised in collaboration with EPC partners

- Ideal for 6 - 100 MW projects

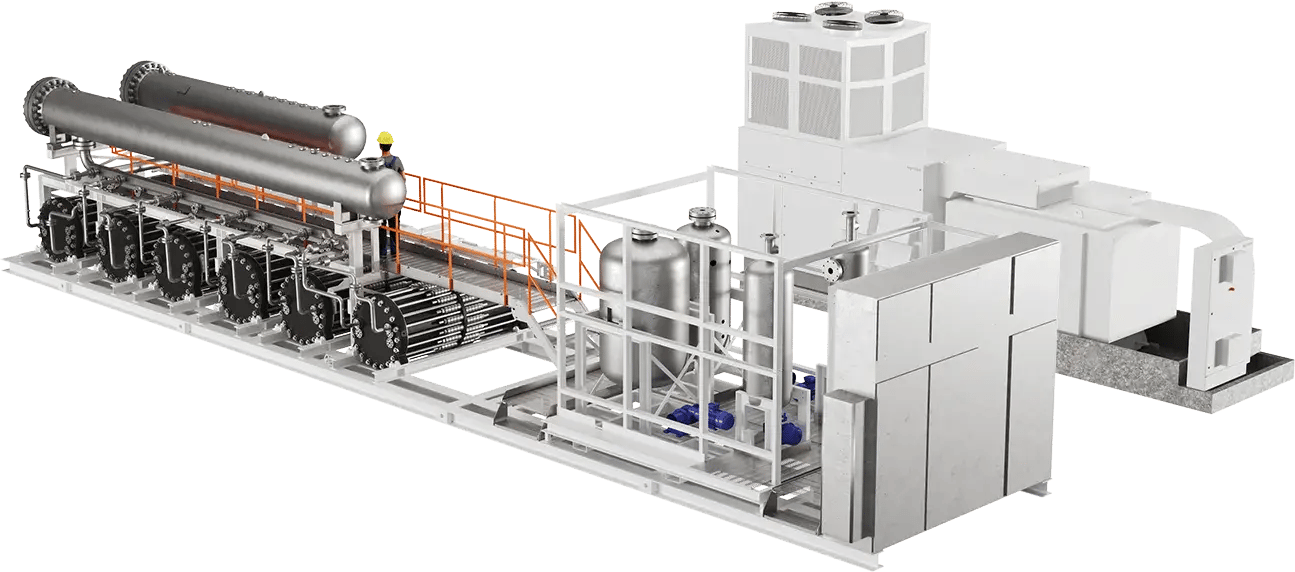

The HyProvide® X-1200 consists of two core modules: a process module and a power supply module. An add-on skid module holds components for gas conditioning (not depicted).

With its compact and modular design and one-end interfaces, the solution is ideal for many large-scale applications - whether used as a stand-alone, turn-key solution or in a cluster configuration.

Explore the HyProvide® X-1200

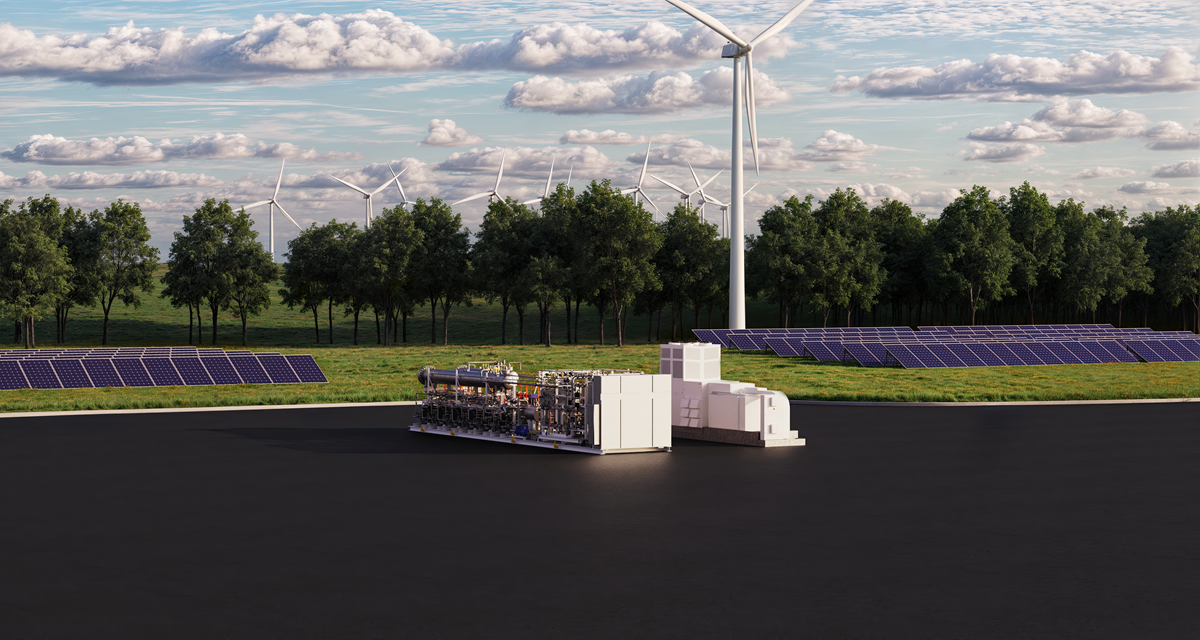

HyProvide X-Series Outdoor Solution

The first outdoor electrolyser designed for large-scale hydrogen production—no dedicated building required. With lower CAPEX & OPEX, multi-stack efficiency, and seamless renewable integration.

Follow the journey

Watch the mini-series following the HyProvide® X1200 6MW prototype from first planning to final tests and learnings towards the commercial product.

Watch the latest episode right here

System Specification

Input details

Output details

Operational details

Our team is standing by to assist you

Projects

to this date

Greenlab P2X 12MW & GreenHyScale 100 MW

Large-scale EU co-funded P2X project consisting of a 100 MW electrolysis plant aiming to demonstrate production using 17 of our HyProvide® X1200 starting with a 12 MW P2X plant.

Read more

Projects

to this date

Greenlab P2X 12MW & GreenHyScale 100 MW

Large-scale EU co-funded P2X project consisting of a 100 MW electrolysis plant aiming to demonstrate production using 17 of our HyProvide® X1200 starting with a 12 MW P2X plant.

Read more

.png)

.png)

#8 reasons to choose

our electrolysers

Mature Technology

Our products are built on commercially proven pressurised alkaline technology.

High Efficiency

One of the most efficient solutions on the market with competitive energy to hydrogen conversion.

Modularity

Modular solutions that are suited for rapid scale-up, clustered solutions and serial production.

Dynamic Operations

The electrolysers are designed for renewable energy and operate dynamically at variable load rates.

Durability

High durability (10+ year stack durability)

and system uptime.

High Output Pressure

The +30 bar hydrogen output pressure allows for a small product footprint and lower compression costs.

Compact Design

Small footprint due to compact modular design increasing number of applications.

Versatility

Its versatile design allows for application across many different market segments for green hydrogen production.

Service adjusted

to your needs

Long-term performance guarantees

Delivering business case certainty and lifetime asset optimisation.

Remote monitoring and support

Remote troubleshooting and operational excellence based on data from online monitoring, field force experience, and R&D learnings.

Spare parts offerings

Leveraging digital tools to offer superior convenience and delivery speed in the supply of spare parts

Customer care function

Providing superior customer journey (performance reporting, issue and request handling, invoicing)

Asset analytics capabilities

Building data infrastructure and analytics (actuarial) as an enabler for performance guarantees